Markforged Maintenance

Keep Your Markforged Printer Running at Peak Performance

Markforged Maintenance

Certified tools and consumables for reliable uptime and part quality

Precision Maintenance Starts with the Right Parts

Markforged printers are engineered for strength, accuracy, and production-ready performance—and keeping them that way requires routine maintenance with OEM-certified components. This collection of genuine Markforged maintenance parts and tools is designed to support everything from nozzle swaps and fiber tube replacements to belt adjustments and purge operations, ensuring your system remains calibrated, clean, and production-ready.

Whether you're maintaining a Desktop Series printer like the Mark Two or servicing an Industrial or Metal X system, these products help you avoid downtime and protect your investment.

Popular Maintenance Categories

-

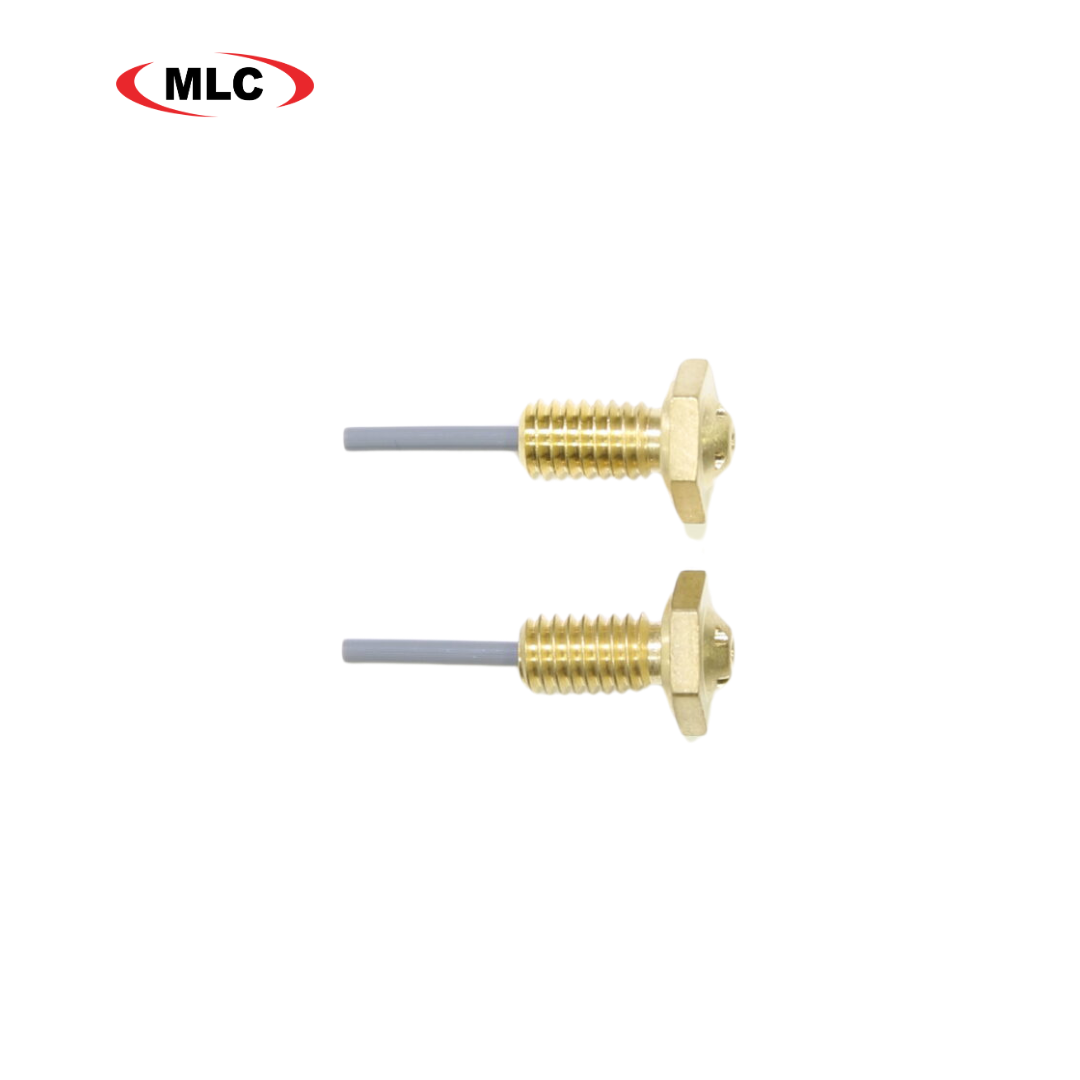

Nozzles & Torque Tools – Ensure clean extrusion and safe, calibrated installation

-

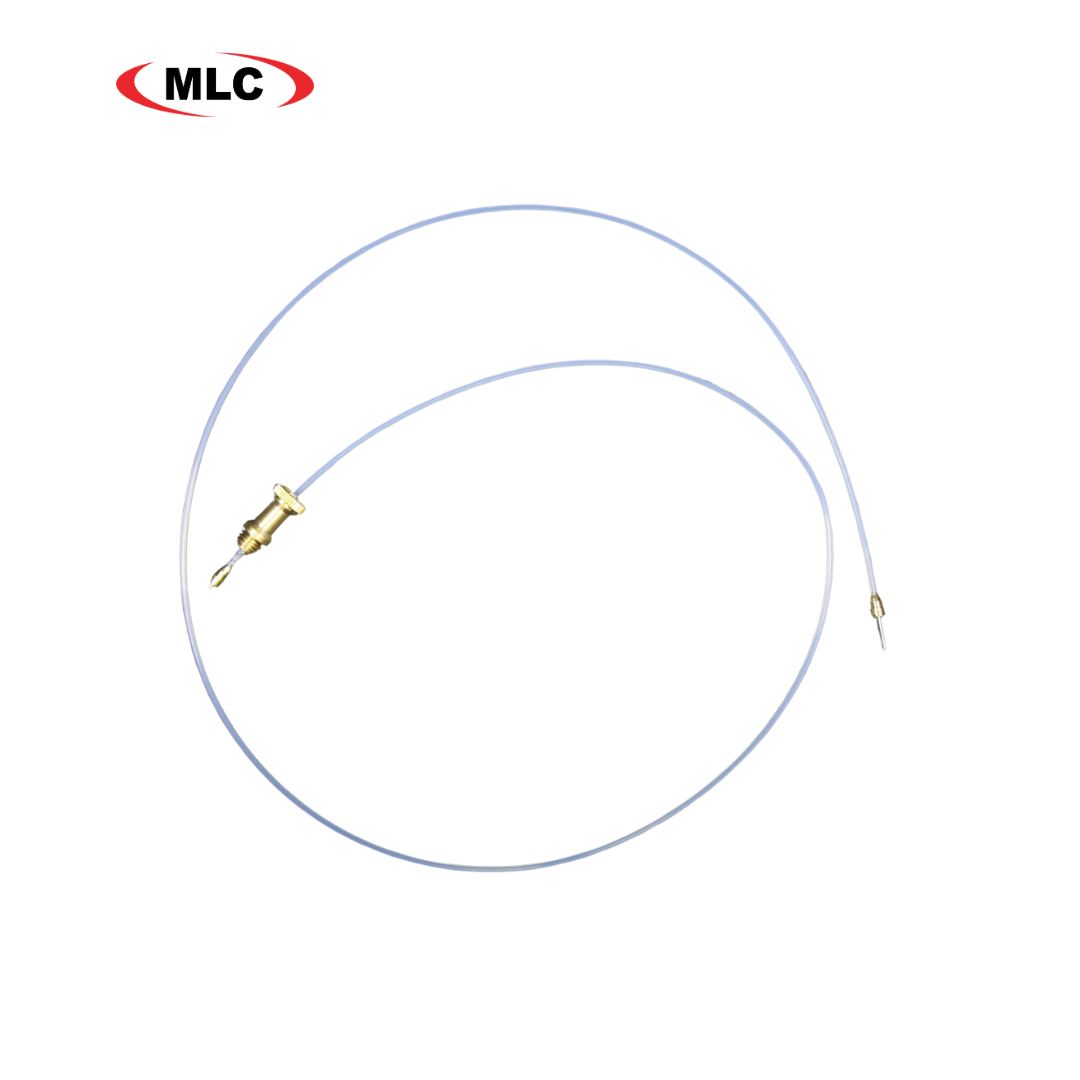

Bowden & Load Tubes – Replace worn guides for smooth material delivery

-

Belts, Pulleys & Motion Parts – Maintain alignment and dimensional precision

-

Print Beds & Shims – Ensure first-layer adhesion and bed-leveling accuracy

-

Gas & Sinter System Filters – For metal printers requiring clean inert atmospheres

-

Purge Kits & Brushes – Keep print paths clean and extrusion smooth

Built for Reliability, Backed by Certification

Every component in this collection is tested to Markforged’s performance standards and designed to maintain machine integrity and print consistency—print after print.